Products and Services

Others

Our range of products, WEFIC® (We Enhance Flow In Control), will offer customers quality as well as cost efficiency.

ORIFICE PLATE CHOKE VALVE

Orifice plate choke valve is used for manifold equipment, such as drilling, fracturing, mud circulating, ground high-pressure gas injecting and producing, etc. The most remarkable feature of the valve is that pressure difference between inlet and outlet can press the two orifice together closely to realize the function of sealing and cutting off when it is closed. Especially in emergencies such as sudden rise or sudden drop of the pressure because of leakage, it closes and cuts off automatically through pre-set pressure signal value of high and low pressure sensor. Thus, accidents can be avoided.

Basic Parameters

- Working pressure: 2000PSI – 20000PSI

- Nominal diameter: 2 1/16” – 4 1/16” (52mm – 103mm)

- Working medium: petroleum, natural gas, mud, gas containing H2S and CO2

- Working temperature: -75°F ~ 350°F

- Material grade: AA, BB, CC, DD, EE, FF, HH

- Specification grade: PSL1 – 4

- Performance requirement: PR1 – 2

CHECK VALVE

This product is designed and manufactured with the requirement of API Spec 6A (Edition 20), meanwhile can be compatible and used interchangeably with domestic and overseas products meeting API 6A standard.

Basic Parameters

- Working medium flows in one direction

- Working pressure: 2000PSI – 20000PSI

- Nominal diameter: 2 1/16” – 4 1/16” (52mm – 103mm)

- Working medium: petroleum, natural gas, mud, gas containing H2S and CO2

- Working temperature: -75°F ~ 350°F

- Material grade: AA, BB, CC, DD, EE, FF

- Specification grade: PSL1 – 4

- Performance requirement: PR1 – 2

FIXED AND ADJUSTABLE CHOKE VALVE

The needle and seat choke features fixed or adjustable model and is made of hardened steel or surfaced hardened wear resistance surfaces to handle standard, corrosive and erosive type of services. The fixed choke has replaceable flow beans with a fixed orifice diameter, whereas, an adjustable choke has an externally controlled variable diameter orifice.

Basic Parameters

- Needle and external sliding sleeve choke valve are mainly used for wellhead Christmas tree

- Valve needle and valve core are made of hard alloy with wear resistance and erosion resistance

- External sliding sleeve choke valve has advantages of low switch torque, throttling as well as shutting off flow

- Working pressure: 2000PSI – 20000PSI

- Nominal diameter: 2 1/16” – 4 1/16” (52mm – 103mm)

- Working medium: petroleum, natural gas, mud, gas containing H2S and CO2

- Working temperature: -75°F ~ 350°F

- Material grade: AA, BB, CC, DD, EE, FF, HH

- Specification grade: PSL1 – 4

- Performance requirement: PR1 – 2

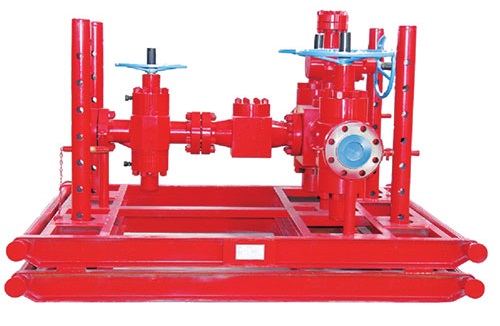

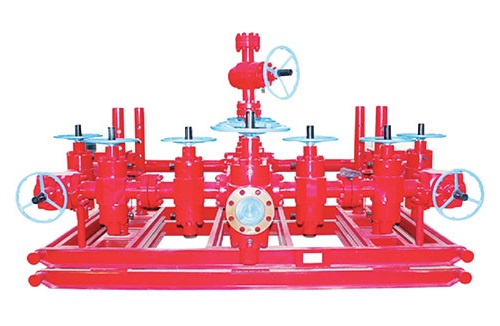

CHOKE & KILL MANIFOLD

Choke and Kill manifold are important well control equipments used for control of overflow and blowout of oil and gas well, implementing near balanced drilling. The choke manifold controls the casing pressure, maintains the balance of downhold pressure through decompression and flow opening, protecting the wellhead. The kill manifold implements well killing operation through pumping well killing liquid into the well, to avoid accident and guarantees safety production.

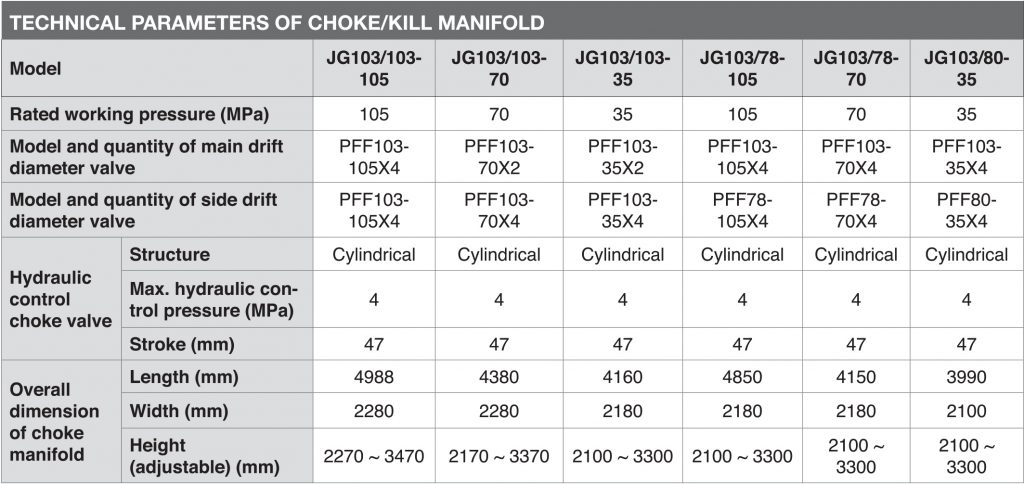

Basic Parameters

- Working pressure: 2000PSI – 15000PSI

- Working medium: petroleum, natural gas, mud, gas

- containing H2S and CO2

- Working temperature: -75°F ~ 350°F

- Nominal diameter: 2 1/16” ~ 4 1/16” (52mm ~ 103mm)

Technical Parameters

CONTROL PANEL

Self-Contained Safety Systems

Single Well Control Panel

Multi-Well Control Panels

Features Standard

- Sequential valve opening and closing

- Monitor flowline pressure status

- Emergency shutdown

- Manual override

- Fire safety shutdown

- Any combination of hydraulic and/or pneumatic valve actuator controls

- Remote telemetry control

- Easy serviceability

- Corrosion resistant type 316 stainless steel (SS)

- Removable doors for easy access to panel components

- Intrinsically safe to meet requirements such as ATEX, U.L., CENELEC, BASEEFA, C.S.A. and others

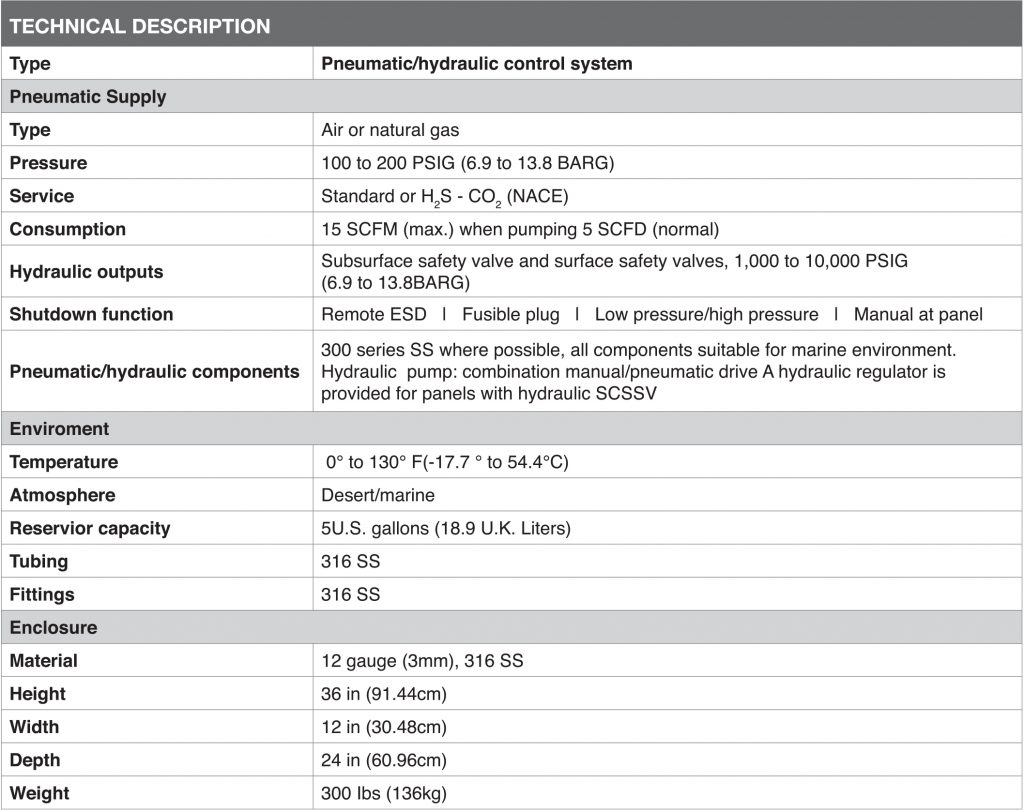

Technical Description